Most shops use epoxy paint to seal their floor, the industrial equivalent of nailpolish (if concrete wore nailpolish). It’s non-porous, which is essential so that oil and coolant won’t seep into the ground water. But the paint itself is as toxic as California will allow (along with the prerequisite treatment of muratic acid); you still need to wear a ventilation mask during application. Oh, and stay away a few days while it dries. (That’s just cancer; don’t get me started about photochemical smog.) Like any status quo, it’s popular because it’s popular. It’s also readily available in many colors; it can stand up to high traffic, including that from tires. In 2-3 years, though, it will weaken and chip, requiring another treatment and the same parade of toxins. In short, for the green garage, an alternative to the epoxy floor is an absolute must.

The green home movement has since developed a selection of concrete treatments like AFM SafeCoat MexeSeal and EcoProCote. The trouble is that they are largely unproven in a truly industrial setting: repeated pressure, sheer and lift from rolling tires and attacks from highly caustic fluids (gasoline, brake fluid).

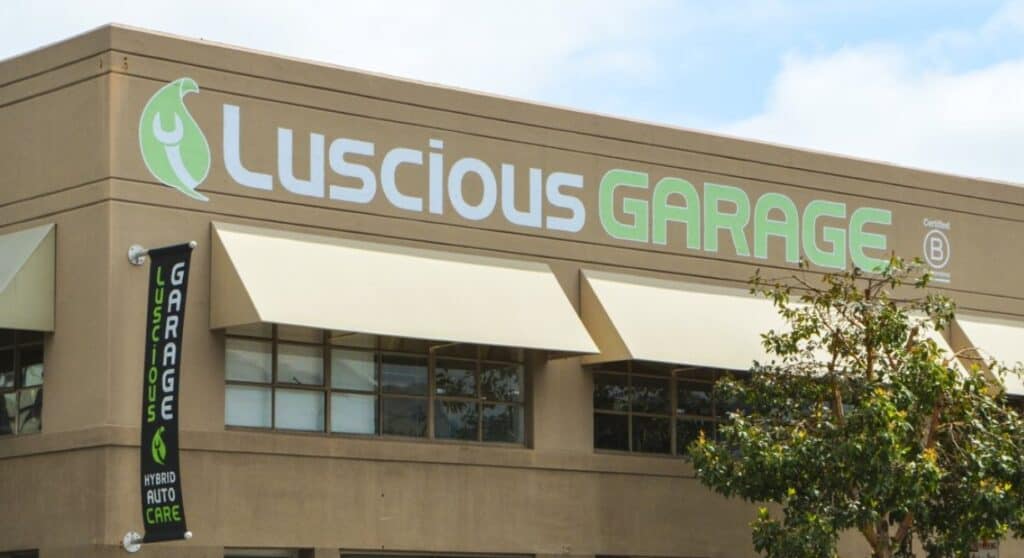

Luscious Garage inherited the original concrete slab at 459 Clementina, dating back ninety years. It had old black paint and lots of chips and cracks. At least we needed to clean all this off before we sealed it. This would essentially leave us with a virgin surface—highly porous, ready to soak up whatever we selected—so we wanted to choose wisely.

We learned the latest fashion in concrete floors is a thing called “RetroPlate”. The idea is simple: take a virgin slab, apply a non-toxic hardener that densifies the stone so much that it becomes non-porous (and very strong). Then polish the hell out of it. The result is very pretty and also very expensive. I hear that several dealerships have used it for their showrooms and shops (including Burlingame Lexus?). It’s also common in restaurants, retail stores, even school cafeterias. It has no coating in the traditional sense, so it never wears away. It actually gets stronger and shinier with age.

So we thought this was a great idea. But would Burlingame Lexus to pay for it?

The good news is that RetroPlate is the second generation of an equally capable treatment. The original product came out over fifty years ago, called “Ashford Formula.” It behaves the same way, is still non-porous, but is not quite as strong or as glossy (40x stronger than regular concrete, versus 500x with RP). As for toxicity, it states, “The Ashford Formula is an odorless and non-hazardous material. It contains no solvents or volatile organic compounds. The Ashford Formula is non-toxic, and produces no harmful fumes or vapors. The Ashford Formula is completely water-based and environmentally safe. Use of this product requires no breathing apparatus or protective clothing.” Best of all, it was within our budget.

CDI Commercial Flooring performed the application this past June. They ground all the cracks and surface imperfections by hand (their arms are as big as my leg) and resurfaced the floor with professional-grade diamond grinders. They used a comprehensive vacuum system that collected all the dust and debris, eliminating particulate matter. The pictures show what a tremendous improvement they made.

If you can’t tell, I am really proud of this floor. Not only is it environmentally sound, it allowed us to extend the life of the existing slab (rather than pour a whole new one). The result brings out the natural imperfections of the stone and all the interesting places it has been extended or repaired. Best of all, it is totally non-porous and non-dust producing. Oh, and it’s fully capable to handle automotive abuse.